Since January 1st 2023, German companies with over 3,000 employees are expected to implement the German Supply Chain Due Diligence Act (SCDDA). For companies with over 1,000 employees, the deadline is 1st January, 2024.

The law aims to prevent social and environmental risk in the supply chain, and sets up new norms for German companies to identify and mitigate such risks resulting from their activities. The law is timely, following a 2022 report from the ILO, Walk Free and IOM found that 27.6 million people are suffering in forced labor conditions, including 11.8 million women and girls and over three million children.

For the first time, it makes it mandatory for companies to manage human rights issues related to Tier 1 suppliers, to appoint a Responsible Person, and to establish processes that proactively identify and mitigate risks. To avoid legal fines and reputational risks, the 3,000 German companies that are affected by the law need to use the German government’s guidelines on due diligence policies, and integrate them with their operations.

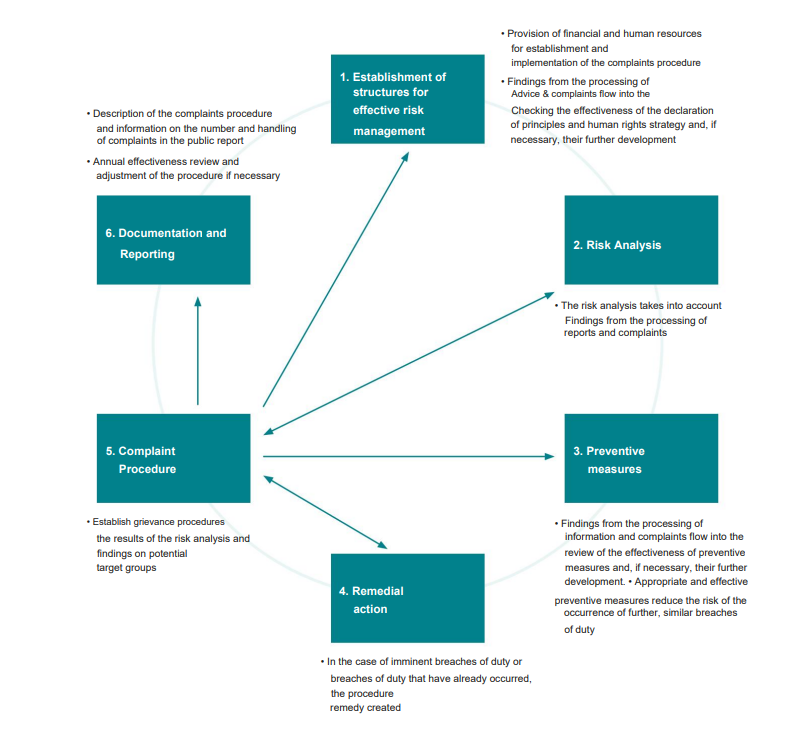

Implementing an effective complaints procedure is a cornerstone of compliance, and new guidance has been released to assist companies in doing so. Here’s our guide to building an effective, SCDDA compliant, complaints procedure.

Know Your Social Impact Disclosure Obligations

Companies are required to complete a questionnaire, which goes beyond a box-checking exercise, as it obliges companies to report progress on the implementation of their human rights due diligence practices. The reporting criteria includes:

- The details of a human rights policy statement;

- How they identify social impact risks in the supply chain;

- How they prioritize those risks;

- How they prevent them;

- How they engage with stakeholders and collect data;

- How they evaluate the effectiveness of these processes.

The guidelines are clear that all stakeholders and persons “who are directly or indirectly affected by the actions of a company and its indirect suppliers” are considered “affected persons.” Companies should therefore prepare for a significant extension of the scope of their complaints procedure that includes all workers in the value chain, not just employers and representatives.

Build An Effective Complaints Procedure

The guidelines helpfully elucidate what is meant by an effective complaints procedure. Specifically, they require that companies establish the following:

- Publicly available rules;

- Publicly defined scope;

- Publicly available, step by step information on their complaints process;

- Who the contact persons are;

- How the company ensures protections against discrimination or punishment for complainants;

- The impartiality of responsible persons.

According to the guidelines, “Grievance procedures offer companies the opportunity to receive feedback on the effectiveness of their risk management and individual due diligence processes.” Companies without an effective grievance mechanism can be fined up to €800,000. In line with the UNGPs and the EU’s CSRD, companies are asked to disclose whether their grievance mechanism can be accessed by supply chain workers, NGOs, unions and affected communities. They are also expected to report on anonymity safeguards for whistleblowers in the supply chain.

A well-functioning complaints procedure forms the basis of proactive risk identification. The grievance mechanism should serve as an “early warning system that allows problems to be identified and, ideally, solved before harm is done.”

Crucially, the level of detail required by German companies raises the bar. The requirements call on companies to detail the number of complaints they received, what sorts of issues these complaints are related to (withheld payments, discrimination, safety, child labor, etc.), and, year on year, to report increases or decreases by case type. As the guidelines state, “companies are recommended to develop and measure suitable Key Performance Indicators. Based on the information and complaints received, developments, trends and patterns can be identified and evaluated”

The complaints procedure is an opportunity for supply chain workers to bridge the social impact information gap, and is a key component of any modernized social impact management system.

Intelligent Design Equals Intelligent Outcomes

A comprehensive risk assessment that’s bolstered by digital survey tools that allow companies to get insights from workers along the value chain, is the foundation of a continuous, worker led, risk management model.

Companies are expected to report on how they evaluate the implementation of their own complaints procedure. In order for companies to evaluate their own processes, they need systems in place that can provide adequate data on their effectiveness.

Ulula’s analytics dashboard provides at a glance macro and micro-level progress updates and ready to use aggregated reports.

The SCDDA asks companies if “there is a process to comprehensively review risk management for its adequacy, effectiveness and appropriate consideration of the interests of (potentially) affected people?“ Achieving this is much easier if affected stakeholders, supply chain workers and communities are involved in the actual process of designing the complaints procedure. This is hinted at in the guidelines, which state that groups identified in the risk analysis should be consulted “when the procedure is designed.” Relevant stakeholders, such as trades union, employee representatives or civil society organizations should also be involved.

German Supply Chain Due Diligence Act (SCDDA) Guidelines

A People Centered Complaints Process

The guidance is clear that, “for different groups of people different access barriers exist” that prevent them from using the system. “These access barriers are often high, especially for vulnerable groups such as children or people who are not literate.” Social impact risks are often high among immigrant worker communities, who may not speak the local language.

In line with the guidelines, “in order to overcome these access barriers, it may be necessary to create various channels through which complaints can be submitted (e.g. by telephone, via an online mask, local contact persons).” This is why Ulula implements digital innovations in the design of their complaints procedures. Co-designing complaints procedures gives companies a better idea of how to prioritize, tailor and target them.

Digitized, anonymous, multi-lingual, remote, technologically neutral and direct-to-worker communications channels help workers to overcome many of the typical barriers to remediation. Digital solutions are more scalable than traditional complaints procedures, like hotlines, and allow companies to roll out effective policies across the supply chain at a reasonable cost.

Through Ulula, our clients can provide supply chain workers access to complaints procedures anonymously with their own devices. This goes a way to ensuring that a complaints procedure “is regarded as trustworthy and promotes and enables the submission of information and complaints even before a breach of duty has occurred,” as stipulated by the guidelines.